Do you need spring steel but the needed dimensions are beyond the manufacturing dimensions?

In this case 75Cr1 might be a possible alternative. Its chemical analysis is comparable to C75S – the most popular spring steel quality.

With 75Cr1 you have got the advantage of expanded widths and thicknesses.

75Cr1 is available in hardening grades: annealed, 42-44 HRC and 48-50 HRC.

| Material | Material Number | US Material Code (AISI/SAE) |

|---|---|---|

| 75Cr1 | 1.2003 | 1075 + Cr |

| Dimension standard |

DIN EN 10051 DIN EN 10048 |

| Supplied Conditions | hot rolled, annealed (75Cr1+AC)) |

| Products |

Sheets |

| Dimensions | Thickness: 1,80–8,30 mm Tolerances according BS EN 10048/10051 Class D, exept thickness:

|

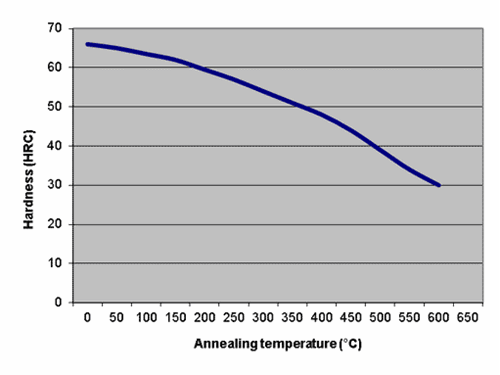

| Heat Treatment | Hardening: Annealing: |

Chemical analysis (in %) according to DIN 17350 table 7

| Material Code | 75Cr1 |

| C | 0,70 - 0,80 |

| Si | 0,25 - 0,50 |

| Mn | 0,60 - 0,80 |

| Cr | 0,30 - 0,40 |

| Remark | Intended use: Stem sheets and circular saws |

erstelle PDF...

erstelle PDF...

Do you need spring steel but the needed dimensions are beyond the manufacturing dimensions?

In this case 75Cr1 might be a possible alternative. Its chemical analysis is comparable to C75S – the most popular spring steel quality.

With 75Cr1 you have got the advantage of expanded widths and thicknesses.

75Cr1 is available in hardening grades: annealed, 42-44 HRC and 48-50 HRCd.

| Material | Material Number | US Material Code (AISI/SAE) |

|---|---|---|

| 75Cr1 | 1.2003 | 1075 + Cr |

| Dimension standard |

DIN EN 10140 |

| Supplied Conditions | cold rolled, bright hardened and tempered (75Cr1+QT): 42-44 HRC and 48-50 HRC |

| Products |

Sheets |

| Dimensions | Tolerances acording BS EN 10140, except Dimensions: 42-44 HRC: |

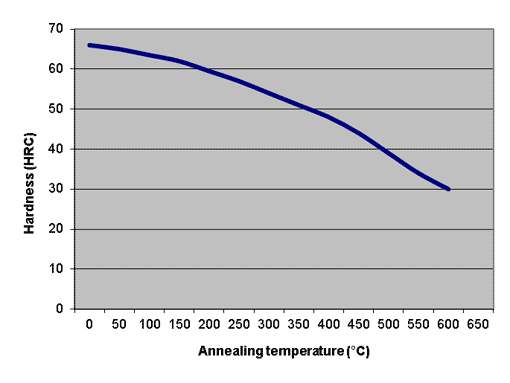

| Heat Treatment | Hardening: 830-860 °C, quenching medium: oil Annealing:

All values without engagement, please contact your hardening shop for details) |

Chemical analysis (in %) according to DIN 17350 table 7

| Material Code | 75Cr1 |

| C | 0,70 - 0,80 |

| Si | 0,25 - 0,50 |

| Mn | 0,60 - 0,80 |

| Cr | 0,30 - 0,40 |

| Remark | Intended use: Stem sheets and circular saws |

erstelle PDF...

erstelle PDF...